Durable Forklift Truck Safety Signs-- Make Sure Compliance in Your Facility

Durable Forklift Truck Safety Signs-- Make Sure Compliance in Your Facility

Blog Article

Key Factors To Consider for Creating Effective Forklift Safety Indications

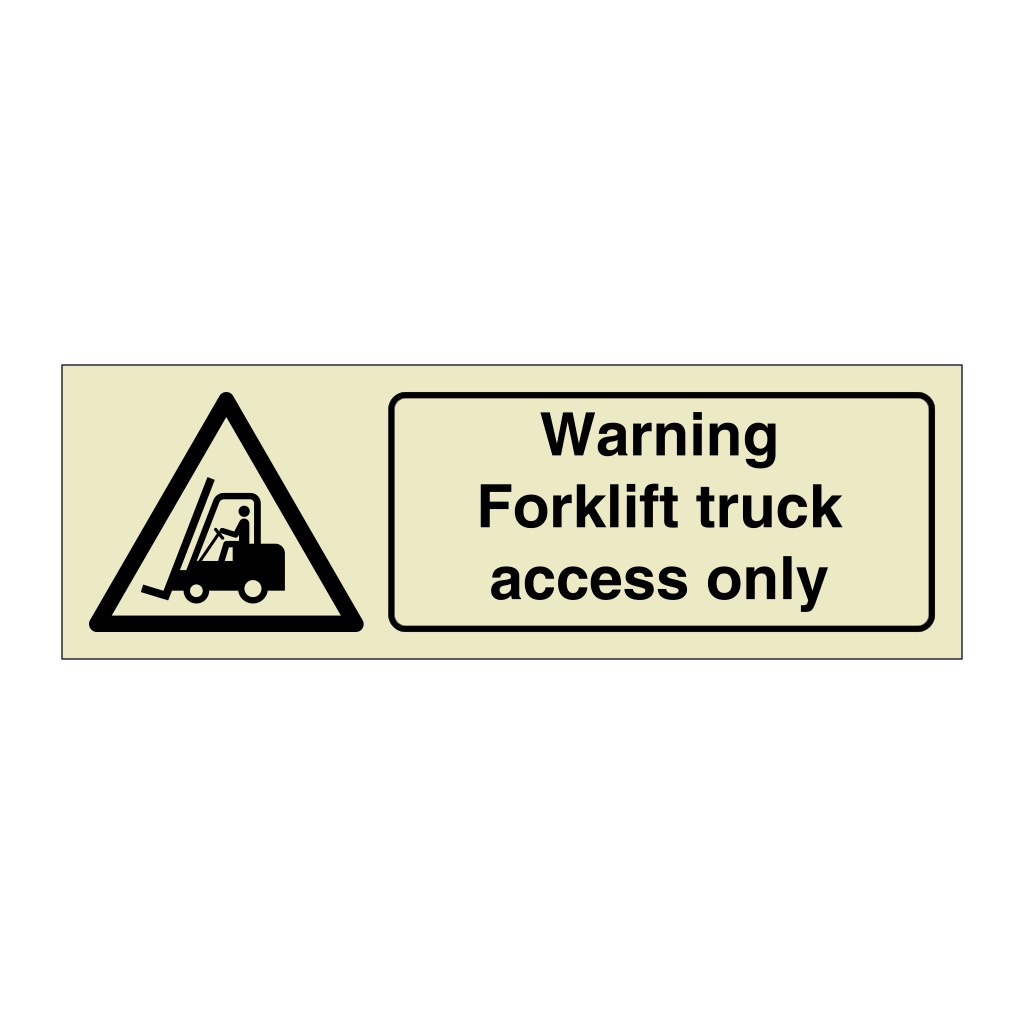

When making effective forklift safety indicators, it is crucial to take into consideration numerous essential elements that collectively ensure optimal visibility and clearness. Strategic placement at eye degree and the use of resilient products like light weight aluminum or polycarbonate more contribute to the durability and efficiency of these indicators.

Color and Contrast

While creating forklift safety indicators, the option of color and contrast is vital to ensuring visibility and performance. The Occupational Safety and Health Management (OSHA) and the American National Specification Institute (ANSI) provide standards for using shades in security indicators to standardize their definitions.

Efficient comparison in between the background and the text or symbols on the indication is just as essential (forklift signs). High comparison guarantees that the indicator is understandable from a range and in differing lighting conditions.

Using proper color and comparison not just follows governing standards but also plays a vital function in maintaining a secure functioning atmosphere by making sure clear interaction of dangers and guidelines.

Typeface Dimension and Style

When creating forklift security indicators, the option of typeface dimension and design is crucial for ensuring that the messages are understandable and swiftly comprehended. The main purpose is to enhance readability, particularly in environments where fast info handling is essential. The font style dimension should be large enough to be read from a distance, fitting varying sight conditions and ensuring that personnel can understand the indicator without unneeded stress.

A sans-serif font style is usually suggested for safety signs because of its clean and uncomplicated appearance, which improves readability. Fonts such as Arial, Helvetica, or Verdana are commonly preferred as they do not have the intricate information that can cover important details. Uniformity in font design throughout all security indications aids in producing an attire and expert appearance, which better enhances the importance of the messages being conveyed.

In addition, emphasis can be accomplished with tactical use of bolding and capitalization. Keyword or phrases can be highlighted to attract instant attention to vital directions or warnings. Nevertheless, overuse of these methods can lead to visual clutter, so it is important to apply them judiciously. By very carefully choosing suitable font dimensions and designs, forklift safety and security signs can efficiently communicate vital security info to all personnel.

Positioning and Exposure

Making certain optimum positioning and presence of forklift safety signs is paramount in commercial settings. Proper indicator positioning can significantly decrease the danger of accidents and improve total workplace security.

Lights conditions likewise play a crucial function in presence. Signs ought to be well-lit or made from reflective products in poorly lit areas to ensure they show up whatsoever times. Using contrasting shades can even more improve readability, especially in atmospheres with differing light problems. By carefully thinking about these facets, one can ensure that forklift safety indications are both reliable and noticeable, thereby fostering a much safer working environment.

Product and Resilience

Picking the ideal products for forklift safety and security indicators is critical to ensuring their long life and performance in commercial settings. Offered the rough problems commonly come across in storage facilities and producing centers, the products picked have to withstand a variety of stressors, including temperature level fluctuations, moisture, chemical direct exposure, and physical influences. Sturdy substratums such as aluminum, high-density polyethylene (HDPE), and polycarbonate are popular selections due to their resistance to these aspects.

Light weight aluminum is renowned for its toughness and rust resistance, making it an exceptional option for both indoor and exterior applications. HDPE, view publisher site on the various other hand, provides remarkable impact resistance and can sustain extended exposure to extreme chemicals without degrading. Polycarbonate, recognized for its high impact toughness and quality, is often made use of where exposure and resilience are paramount.

Equally crucial is the sort of printing utilized on the indicators. UV-resistant inks and protective layers can substantially improve the life expectancy of the signage by stopping fading and wear triggered by long term direct exposure to sunlight and various other ecological elements. Laminated or screen-printed surfaces supply added layers of protection, making sure that the crucial safety and security information stays understandable over time.

Purchasing high-grade materials and robust manufacturing processes not only extends the life of forklift security indicators but likewise enhances a society of safety within the work environment.

Conformity With Rules

Following regulatory standards is critical in the style and release of forklift safety and security signs. Compliance guarantees that the indications are not only efficient in sharing essential safety information but also meet legal obligations, thus alleviating prospective obligations. Different companies, such as the Occupational Security and Health And Wellness Management (OSHA) in the United States, supply clear standards on the specs of safety indicators, including shade plans, message size, and the addition of widely recognized symbols.

To follow these regulations, it is vital to perform a thorough testimonial of suitable requirements. As an example, OSHA mandates that safety indicators need to show up from a see page range and include particular colors: red for danger, yellow for care, and environment-friendly for safety and security directions. Additionally, sticking to the American National Specification Institute (ANSI) Z535 series can better improve the effectiveness of the indicators by standardizing the design elements.

Furthermore, routine audits and updates of safety and security indications should be executed to guarantee recurring compliance with any kind of modifications in regulations. Involving with certified security professionals throughout the design stage can also be useful in ensuring that all regulative needs are satisfied, and that the indicators serve their desired purpose properly.

Conclusion

Designing effective forklift security signs needs mindful attention to shade comparison, font size, and style to make certain optimum visibility and readability. Adherence to OSHA and ANSI standards standardizes safety messages, and integrating reflective products enhances exposure in low-light scenarios.

Report this page